An important update is available for FreeStyle LibreLinkØ. Check here for more information.

Menu

Menu

08 Oct 2019

Let’s start with a story:

I was coaching a dairy factory somewhere in the world with a Listeria problem. The factory had realised that a persistent presence of Listeria was not a good thing and were set on improving. On one of my visits, their manager said “You know Jack, we keep finding Listeria in that area and are on continuous traceback – it’s costing quite a bit!” He was not kidding. They were doing hundreds of samples every month! At this point, I not-so-carefully pointed out that if you keep sticking your swab in a turd, you shouldn’t be surprised to find shit. You see, the area in question was very old, with pooling water and in need of a new floor. Really, all those test dollars were just to confirm what they already knew.

This is one example of a well-intentioned test routine, which is adding little value. My logic is that if you are going to spend money on testing, the result needs to have some meaning and add to our understanding of the plant, the process or the product.

It’s quite remarkable how often I come across the “test for test sake” approach with little thought about the information we collect or what the results will tell us. Being a frugal guy, I cannot emphasise enough that you should spend your testing dollars wisely, with a clear plan and purpose.

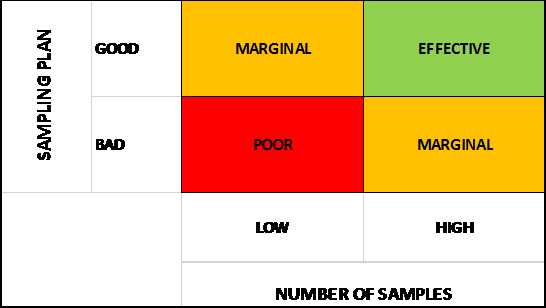

Below is a picture I use for Environmental Pathogen Management. I come across all four quarters during my global travels but unfortunately, the green one is rare. I feel this diagram works for most of our testing, because without a clear sampling plan, you are likely to waste some money.

In 2016, I wrote an article on the value of micro testing in the food industry. In the article I introduced the term “utility value”, which is determined by asking yourself two questions:

My introductory story clearly illustrated the answer to the first question, the answer being “nothing new.”

But what about the downside cost? Here’s another story to consider.

I walked into this fast moving consumer good (FMCG) factory and had a look at their testing plans. The team had (rightly) decided to test some of their final product for pathogens. However, being fast moving, the product was already out of the door before the results were known. Management had failed to anticipate the impact of a positive result and the enormous potential downside cost associated with a (unavoidable) recall. They did not “expect the unexpected”.

When I come across this situation I call it Russian roulette testing, because at some point the gun will go off. Fortunately for FMCG plants, rapid pathogen tests are now available and are a great tool to speed up product release with confidence, free up working capital and keep customers happy because of faster delivery.

In general, finished product testing has a low utility value. If the result is out of spec, we often don’t know why (low information value) and have to rework or downgrade the product (high downside cost). Unfortunately, the global food supply chain spends most of their testing dollars on final product, in order to comply with demands from customers and regulators, which is non-discretionary.

To me, in-process testing to verify plant and process hygiene is a much more effective use of our food testing budget and has the highest utility value, because an in-process result provides useful information (plant not clean!) and has a low downside cost (product is not yet lost!).

So remember, before you send a sample away for testing, ask yourself: “to test or not to test?” and make sure you test with the end in mind!

For more info, here’s the link to my 2016 article.

With over 30 years experience in the global food industry, Jack has led the international food safety assurance team at Fonterra and is currently working as an independent consultant. Jack has managed consultancy projects in the USA, Europe and China and led the design of Fonterra’s Environmental Pathogen Monitoring Programme. If you would like to get in contact with Jack, you can do so by emailing him at jack.vds@xtra.co.nz.

If you enjoyed reading our articles, why not sign up to our blog mailing list? You'll get new articles straight to your inbox as they're released!